At CPV, we strive to minimise our organisation’s impact on the natural environment.

All of our waste materials are reprocessed and reused as second-grade raw materials in the manufacture of plastic products. In addition to this, we have been carefully managing the 85-acre site that accommodates our production facility and headquarters – having recently planted 20 acres of mixed woodland to encourage wildlife. It is also our aim to generate our on-site energy requirements from sustainable sources in the coming years – further reducing our carbon emissions.

More Features & Information

Design & Engineering

Our team of engineers offer a full design service for all of our systems. From 3D product design, stress analysis and engineering, through to training, on-site testing and installation support – our clients can ensure the very best solution to their application.

Innovation

We operate in a wide array of sectors, with products satisfying many applications. Our state-of-the-art production facility – based at the site of our headquarters near Romsey in Hampshire, England – backed by a selection of research, design, engineering, testing, quality, training and support services.

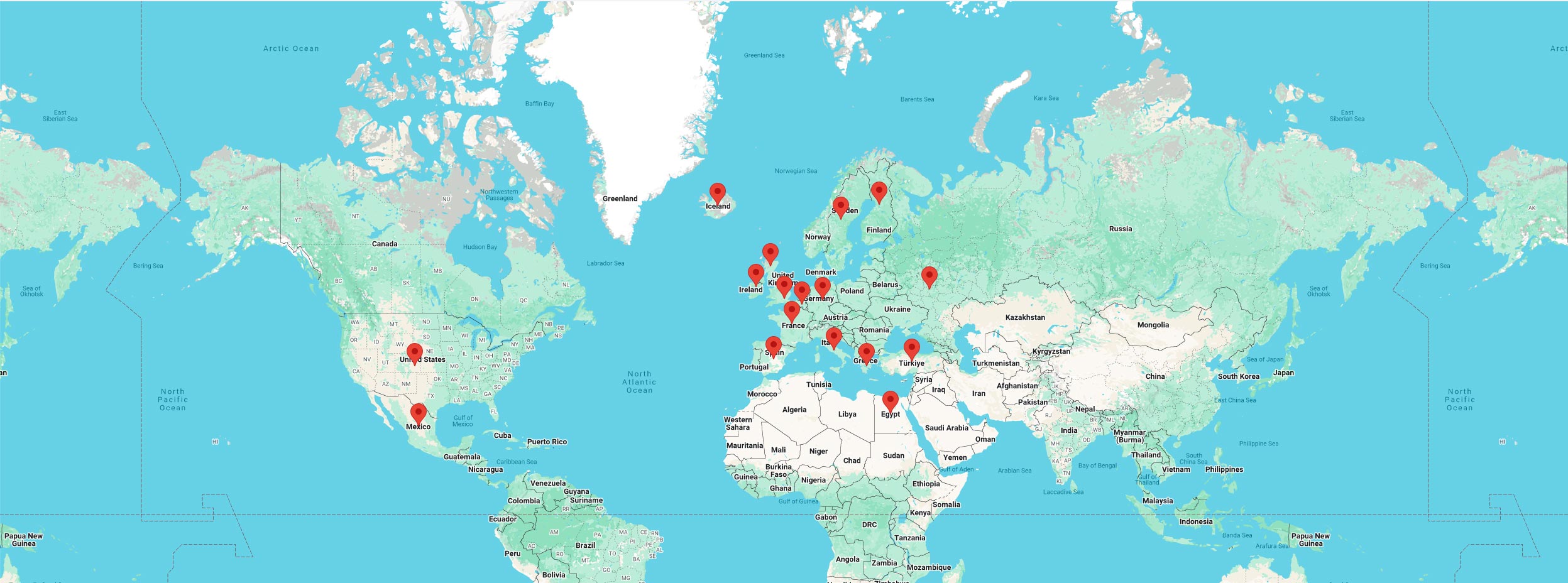

A World-Class Company

CPV was a pioneer in the development of thermoplastic pipe systems and, to this day, we are still committed to driving forward innovation in products, services and manufacturing techniques. This not only improves the way in which our products perform, but it often lowers our clients’ capital and operational expenditure.

Quality Assurance

With the objective of providing total customer satisfaction, CPV maintains an effective and efficient total quality management system which complies with BS EN ISO 9001. This system is continually reviewed for effectiveness and continual improvement – feedback from which is helping shape company objectives.

Get In Touch

Durable polymer lasts 150+ production cycles

100% recyclable

Substantial cost savings compared to fiber cores

Reduced CO₂ emissions