Polymer Cores Specifically Designed for the Demanding Landscapes of Tissue and Paper Manufacturing

Substantial Savings

Significantly extended service life, fewer replacements and fewer deliveries all contribute to huge savings, which mills can begin achieving in as little as 12 months.

Durable

CPV’s specially-formulated polymer material enables significantly more rotations than traditional cardboard (fiber) alternatives.

Sustainable Solution

Helping mills achieve sustainability goals through being fully recyclable and by offering a lower carbon footprint when compared to traditional alternatives.

Benefits

UltraCORE is long-lasting and reduces downtime, as well as eliminating regular disposal charges.

Custom Solution

UltraCORE can be manufactured in a range of custom colors, assisting with identification and tracking, alongside the fitting of RFID tags.

A mother reel core specifically designed for paper and tissue manufacturing

Being incredibly robust, CPV’s UltraCORE offers a significantly extended service life compared to traditional fiber cores. Manufacturers enjoy substantial reductions in operating costs, whilst ensuring greater sustainability and environmental benefits for their business.

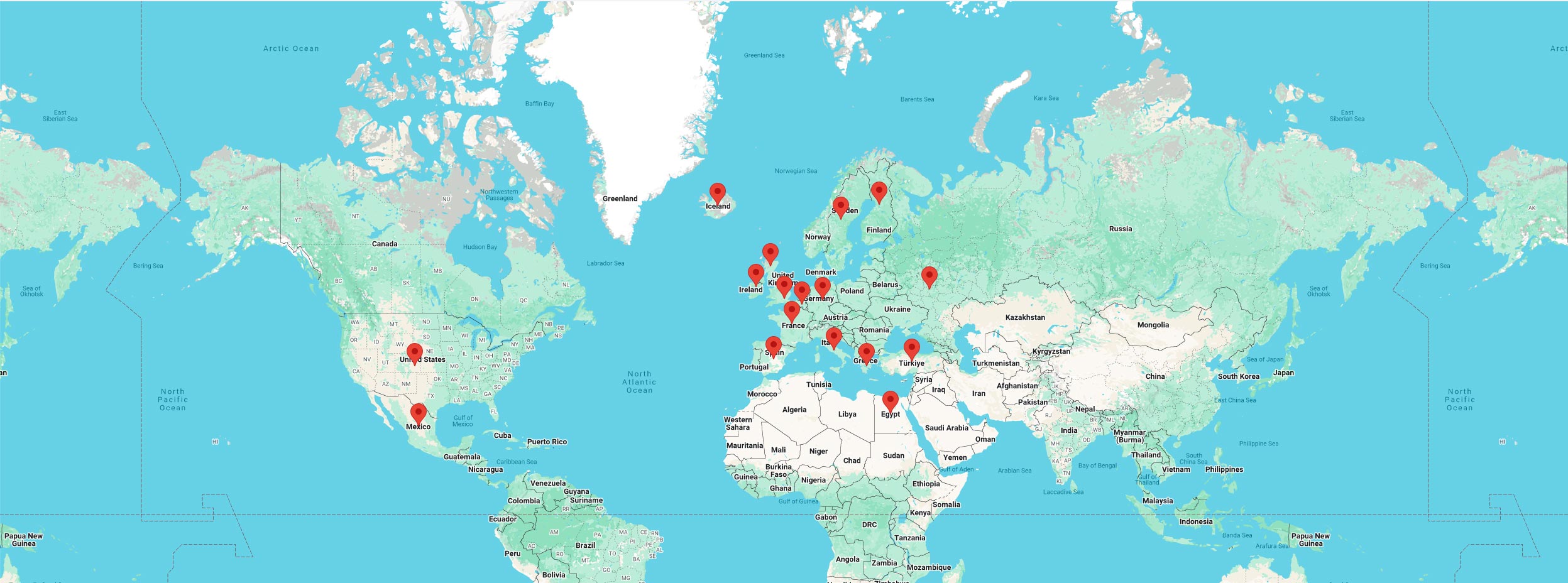

Now in its eighth decade at the forefront of technical polymer and composite-based innovation for industry, CPV is supporting the paper and tissue manufacturing industries’ drive to ensure their products are produced in the most sustainable and cost-effective way.

UltraCORE is Independently EPD Verified for Proven Environmental Performance

UltraCORE holds an independently verified Environmental Product Declaration (EPD) from BRE Global Ltd, confirming its full lifecycle environmental performance. Verified to EN 15804 and ISO 14025 standards, the EPD provides transparent, comparable data – proving UltraCORE’s sustainability claims are backed by rigorous third-party assessment, not assumptions.

Proven Solution

Having carried out trials with some of the UK’s leading mills in the early 1990s – it was quickly found that using a core extruded from CPV’s specially-formulated polymer material enabled substantially more rotations than traditional cardboard (fiber) alternatives.

Now soon to be entering the fourth decade since the trials began, mills using CPV’s polymer cores are enjoying significant financial savings every year, with their investment typically achieving payback within the same financial year.

Highly Durable Polymer

Core production cycles

Sustainable Cost Savings

Compared to cardboard (fiber) cores

Approx. 20x Longer Lasting

Compared to traditional core solutions

Why Choose UltraCORE?

Colors

Our polymer cores are available in a multitude of colors, with options for permanent extruded colored stripes and over-printed text.

Durable & Reliable

Polymer cores have been proven to last in excess of 25 years, whereas cardboard (fiber) cores typically last a maximum of eight rotations. We have clients using cores that are now in their third decade!

Savings

Mills switching to polymer cores enjoy significant financial savings and typically achieve a payback within 12 months.

Dimensions

Our polymer cores are accurately manufactured to meet our customers’ exact requirements in sizes up to 24 inches (600mm) OD.

RFID

Our polymer cores can incorporate RFID tags to enable traceability in the factory and monitoring of reel weights.

Finishes

Options are available for different surface finishes, chamfering and further customisation to meet every requirement.

100% Recyclable

Polymer cores have a lower carbon footprint when compared to cardboard (fiber) alternatives. Even after a long service life, polymer cores can be easily recycled.

Reduced Downtime

With longer-lasting polymer cores, sites will experience an increase in efficiency.

Weather Resistant

CPV polymer cores be stored outside in most weather conditions, freeing up internal storage space.

Make the Switch

Mills switching to polymer cores typically benefit from up to six-figure financial savings and a payback within 12 months.